Please use the following filters to explore our news stories, articles and insights.

8 Reasons to Choose Enfield Tubes

The Harvard Business Review article, Competing on the Eight Dimensions of Quality, proposed that companies know they have to improve the quality of their products because, alas, customers have told them so. The suggestion was that, relatively few companies had learned to compete on quality with the principles of quality control often defensive and narrow in scope, focused on eliminating defects. The article continued to advocate for the use of high quality as a competitive linchpin.

At Enfield Tubes, we see high quality as pleasing customers, not protecting them from frustration and to this end we have engineered our thin wall, high frequency welded tubes along the eight dimensions of product quality prescribed by the review:

Performance

Cooling system efficiency and the elimination of leaks is a vehicle priority. HF seam welded tubes from Enfield Tubes in the core of a vehicle radiator help reduce the risk. Our quality tests are rigorous, even destructive, designed to ensure the tubes perform far in excess of the typical working pressure and consequently, show an increased durability and reliability in service.

Features

Amongst the various features of our HF seam welded tubes we offer a dimple variant. The dimpled tube exhibits a larger heat transfer rate than a plain tube and both the water side and air side heat transfer coefficients are larger than the plain tube. When applied to a radiator core the improvement brought about by the dimpling is primarily, as a result of changing the heat transfer characteristics of the air side primary surface.

Get our free dimple whitepaper now >

Reliability

Manufactured for reliability, we routinely and rigorously test our tubes during production to ensure that every length performs in its intended application over a long period of time. The structural integrity of the weld is such that burst pressure tests always result in substrate failure. This is the best type of failure and indicates that the strength of weld is exactly right for the product and its performance.

Watch our burst pressure test video >

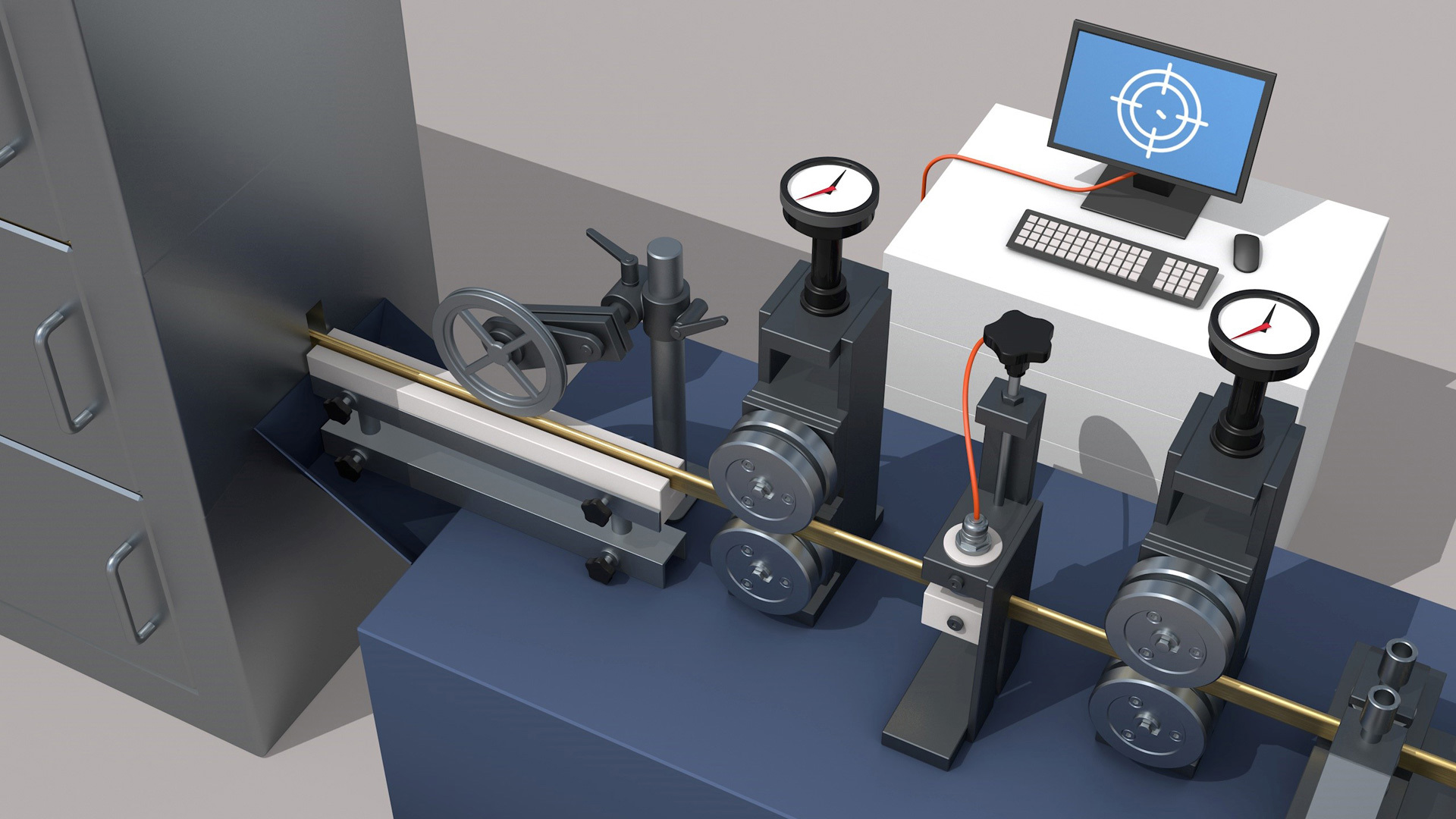

Conformance

Conformance starts at origination with the sourcing of raw materials, supplied according to an exacting specification and supplied with full test certificates. Once into production, we maintain traceability with an identifier printed at prescribed intervals on the inside of the tube. All dimensions are maintained within specification using SPC and while maintaining the process in control, we also use the data to guide our process and product improvements – to ensure repeatability and reproducability for an exceptional fit with mating parts from the radiator core.

Conformance also means making it easy for the customer to do business with us, eliminating mistakes and working across the supply chain to ensure delivery accuracy.

Durability

Durability is a measure of the products life and the ability to last a long time without significant deterioration. A durable product also helps the environment by conserving resources and reducing waste. Accelerated core fatigue tests, based on a specification calculated from Weibull analysis, to measure the product life repeatedly display our product’s durability.

Servicability

While designed for reliability and durability, our solder coated brass tubes are repairable in the field, a principal reason for these tubes being the preferred solution for heavy duty, off-highway applications, where downtime would otherwise be particularly damaging.

Aesthetics

Our product is concealed yet critical. Assembled into a sealed unit, aesthetics could be considered of little consequence for this utilitarian product. However, we are committed to supplying the very best tubes bar none and employ both in-line controls as well as strict visual quality control checks at the end of the mill prior to packaging. Furthermore, we exercise great care with our packaging to protect the product and present it in the best way to our customers.

Perceived Quality

Reputation is a function of what we do and ultimately, how customers perceive our product and service. We’ve been manufacturing heat exchanger tubes every day since 1942. We think we’re good at it but see what our customers say. Our belief is in a measure of reputation that is in large part, based on customer loyalty and on that basis we are more than happy.